谘詢電話

13924666952

400-158-1606

深圳街頭驚現機器人警察!

安檢機器人地鐵站上崗執勤!

全球首例!機器人集體(ti) 進廠“打螺絲(si) ”

........................................

不少網友看完直呼

Robot policemen have astonishingly appeared on the streets of Shenzhen! Security inspection robots have started to perform their duties at the subway stations! The world's first case! Robots collectively enter the factory to "screw bolts" !.................. Many netizens exclaimed after seeing these:"It's so advanced. The scientific and technological strength is really formidable. Shenzhen truly lives up to the reputation of being the capital of technology!"

近段時間,深圳各種機器人在不同領域大顯身手,網友驚歎的“硬核科技”,背後是深圳機器人產(chan) 業(ye) 從(cong) 研發到落地的全鏈路爆發,這些案例不僅(jin) 是技術展示,更是產(chan) 業(ye) 鏈協同創新的成果——它們(men) 需要核心零部件、算法開發、場景適配等全環節配合。

In recent times, various types of robots in Shenzhen have demonstrated their capabilities in different fields. Behind the "hardcore technology" that has amazed netizens is the full-link explosion of Shenzhen's robot industry, from research and development to implementation. These cases are not just demonstrations of technology, but also the achievements of collaborative innovation in the industrial chain — they require the coordination of all aspects, including core components, algorithm development, and scenario adaptation.

4月24日至26日,“機器人全產(chan) 業(ye) 鏈接會(hui) (FAIR plus 2025)” 將在深圳會(hui) 展中心舉(ju) 辦,讓我們(men) 一起來近距離體(ti) 驗這些“硬核科技”,共赴機器人全產(chan) 業(ye) 鏈大規模嘉年華!

From April 24st to 26th, the "Robot Full Industry Chain Link Conference (FAIR plus 2025)" will be held at the Shenzhen Convention and Exhibition Center. Let's come and experience these "cutting-edge technologies" up close and attend this large-scale carnival of the entire robot industry chain together!

01

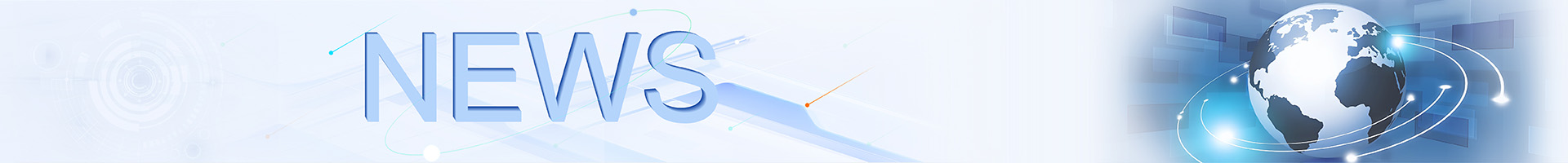

機器人可以幫我們(men) 做什麽(me) ?

在餐廳,酒店等服務場景,它們(men) 化身服務員、調酒師,能精準地完成送早餐,調飲料等精細操作。在工業(ye) 領域,它們(men) 既能分揀微小零件,又能完成精密裝配等協同作業(ye) ,還能替代人工完成危險的噴塗焊接等工作。從(cong) 智能服務到工業(ye) 製造的精密世界,機器人正全方位融入我們(men) 的生活與(yu) 生產(chan) 。

In service scenarioses such as restaurants and hotels, they transform into waiters and bartenders, and can precisely perform delicate operations like delivering breakfast and mixing beverages. In the industrial field, they can not only sort tiny parts but also carry out collaborative tasks such as precision assembly. Moreover, they can replace humans in performing dangerous jobs like spraying and welding. From intelligent services to the precise world of industrial manufacturing, robots are comprehensively integrating into our lives and production.

每一個(ge) 能“看得見”的機器人應用,背後都凝聚著“看不見”的技術突破

Behind every "visible" application of robots lies an "invisible" technological breakthrough.

以工業(ye) 機器人為(wei) 例,控製係統是機器人的“大腦”,是決(jue) 定機器人功能和性能的主要因素。控製係統通過輸入程序向驅動係統和執行機構發出指令信號,完成運動控製。工業(ye) 機器人控製技術的核心任務包括工作空間內(nei) 的運動範圍、姿態、軌跡及動作時間等。

Taking industrial robots as an example, the control system is the "brain" of the robot and is the main factor determining the functions and performance of the robot. The control system sends command signals to the drive system and the actuator through the input program to complete the motion control. The core tasks of industrial robot control technology include the motion range, posture, trajectory, and action time within the workspace, etc.

yl34511线路中心工控自主研發的驅控一體(ti) 集成技術,讓機器人變成即插即用的一體(ti) 式自動化裝置。此次展會(hui) ,我們(men) 將攜新一代具身智能控製係統及多關(guan) 節機器人控製係統亮相FAIR plus 2025。

The integrated drive and control technology independently developed by Huacheng Industrial Control System makes the robot an all-in-one plug-and-play automated device. At this exhibition, we will showcase the new generation of embodied intelligence control system and multi-joint robot control system at FAIR plus 2025.

02

具身智能機器人控製係統

Embodied Intelligence Robot Control System

A high-performance and highly flexible intelligent control solution

2025年政府工作報告中,“具身智能”首次被寫(xie) 入,與(yu) 生物製造、量子科技、6G等一同被列為(wei) 未來產(chan) 業(ye) 培育的重點方向,使得具身智能再次成為(wei) 關(guan) 注的焦點。那到底什麽(me) 是具身智能呢?簡單地說,具身智能是指智能體(ti) (如機器人、無人機、智能汽車等)通過物理實體(ti) 與(yu) 環境實時交互,實現感知、認知、決(jue) 策和行動一體(ti) 化。

In the Government Work Report of 2025, "embodied intelligence" was written into it for the first time. Together with biological manufacturing, quantum technology, 6G, etc., it was listed as one of the key directions for the cultivation of future industries, which made embodied intelligence once again become the focus of attention. So, what exactly is embodied intelligence? Simply put, embodied intelligence refers to the integration of perception, cognition, decision-making, and action achieved by intelligent agents (such as robots, drones, intelligent vehicles, etc.) through real-time interaction with the environment via physical entities.

yl34511线路中心工控具身智能控製係統是一款高性能、高靈活性的智能控製解決(jue) 方案,支持拖動示教、雙臂協同作業(ye) 和七自由度運動控製,該係統采用先進的運動規劃算法,提高作業(ye) 精度和靈活性,降低編程和調試成本。廣泛適用於(yu) 裝配焊接、搬運碼垛、醫療服務、教育科研等場景。

The Embodied Intelligence Control System of Huacheng Industrial Control System is a high-performance and highly flexible intelligent control solution. It supports drag teaching, dual-arm collaborative operation, and motion control with seven degrees of freedom. This system adopts advanced motion planning algorithms, which improve the operation accuracy and flexibility and reduce the programming and debugging costs. It is widely applicable to scenarioses such as assembly welding, handling and palletizing, medical services, education and scientific research.

雙臂協同、精準高效 Dual-arm collaboration, precise and efficient 支持鏡像、對稱等協同運動模式,雙臂實時同步,輕鬆完成複雜抓取、裝配任務,顯著提升作業(ye) 效率與(yu) 精度。 It supports collaborative motion modes such as mirror imaging and symmetry. The two arms are synchronized in real time, enabling the easy completion of complex grasping and assembly tasks, and significantly improving the ope-ration efficiency and accuracy. | |

拖動示教、編程便捷 Drag teaching, convenient programming 具備拖動示教功能,無需複雜編程即可快速設定動作軌跡顯著降低調試與(yu) 部署成本,提升易用性。 It has the function of drag teaching. The motion trajectory can be quickly set without complex programming, which significantly reduces the debugging and deployment costs and improves the ease of use. | |

智能防碰撞、安全作業(ye) Intelligent anti-collision, safe operation 實時檢測雙臂間距,觸發防碰撞預警,有效規避機械幹涉,保障設備與(yu) 人員安全。 It can detect the distance between the two arms in real - time, trigger the anti - collision warning, effectively avoid mechanical interference, and ensure the safety of equipment and personnel. |

03

多關(guan) 節機器人控製係統

yl34511线路中心工控多關(guan) 節機器人控製係統采用驅控一體(ti) 化架構,能夠直接獲取機械臂實時信息,顯著提升響應速度。同時憑借高精度控製、柔性化設計,可搭配多種工藝包,為(wei) 工業(ye) 自動化提供了高效、靈活的解決(jue) 方案。

The multi-joint robot control system of Huacheng Industrial Control System adopts an integrated drive and control architecture, which enables it to directly obtain the real-time information of the robotic arm, significantly improving the response speed. At the same time, with its high-precision control and flexible design, it can be equipped with a variety of process packages, providing an efficient and flexible solution for factory automation.

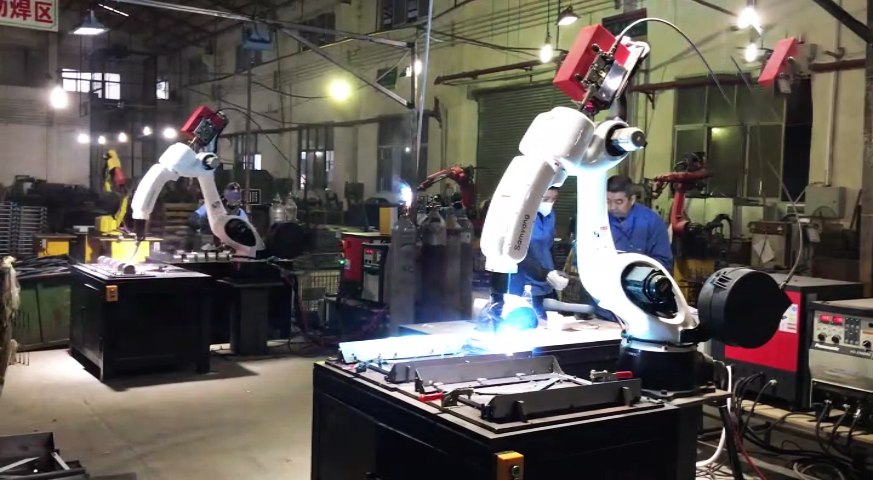

3C行業(ye) 精密裝配

Precision Assembly in the 3C Industry

3C行業(ye) 生產(chan) 具有高精度、高速度、高靈活性的需求,多關(guan) 節機器人控製係統控製精度達0.01mm,可精準完成零部件的高精度點膠和焊錫操作。應用於(yu) 3C產(chan) 品的裝配、點膠、焊錫、鎖付螺絲(si) 等工序。

The production in the 3C industry has the demands for high precision, high speed and high flexibility. The control precision of the multi-joint robot control system can reach 0.01mm, enabling it to precisely complete high-precision dispensing and soldering operations of components. It is applied to the processes such as assembly, dispensing, soldering and screw locking of 3C products.

搬運碼垛,解放雙手

Handling and palletizing, liberate your hands.

傳(chuan) 統的人工碼垛方式不僅(jin) 勞動強度大,而且效率低下。該係統憑借其精準的運動控製能力,能夠高效、安全地完成碼垛作業(ye) 。在物流倉(cang) 儲(chu) 、食品包裝等行業(ye) 可實現物料堆垛與(yu) 搬運。

The traditional manual palletizing method not only involves high labor intensity but also has low efficiency. Relying on its precise motion control capabilities, this system can efficiently and safely complete palletizing operations. It can be used for material stacking and handling in industries such as logistics warehousing and food packaging.

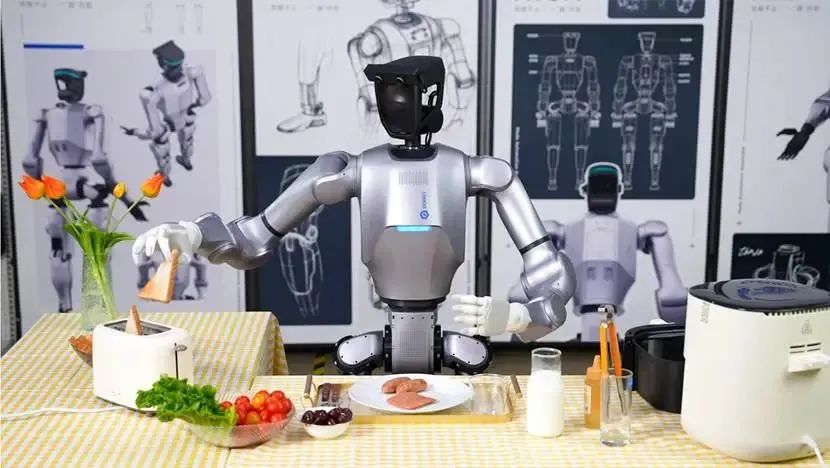

噴塗焊接 安全高效

Spraying and welding, safe and efficient

係統具備高精度運動控製和軌跡規劃能力,在汽車零部件、金屬加工等領域可實現噴塗的均勻覆蓋和焊接的精準操作,有效解決(jue) 了人工操作的安全隱患,同時提升了生產(chan) 質量與(yu) 效率。

The system has the capabilities of high-precision motion control and trajectory planning. In fields such as automotive parts and metal processing, it can achieve uniform spraying coverage and precise welding operations. It effectively addresses the potential safety hazards of manual operations, and at the same time, improves production quality and efficiency.

4月24-26日

深圳會(hui) 展中心(福田)7-8號館

即刻報名,共赴這場硬核科技展會(hui) !

🔺掃碼報名免門票🔺

From April 24st to 26th, in Pavilions 7-8 of Shenzhen Convention and Exhibition Center (Futian). Sign up right away and come together to attend this hardcore technology exhibition!

版權所有 © 深圳市yl34511线路中心工業(ye) 控製股份有限公司 未經許可不得複製、轉載或摘編,違者必究 版權聲明

Copyright © Shenzhen Huacheng Industrial Control Co., Ltd. All Rights Reserved.

網站ICP備案號:

技術支持: